Table of Contents

- Understanding the Concept of Block Shear Failure

- Factors Contributing to Block Shear Failure

- Analyzing Block Shear Capacity

- Design Considerations to Prevent Block Shear Failure

- Examples of Block Shear Failure in Real-World Structures

- Preventive Measures and Best Practices for Avoiding Block Shear Failure

- Conclusion: Importance of Addressing Block Shear Failure in Structural Design

#Understanding the Concept of Block Shear Failure

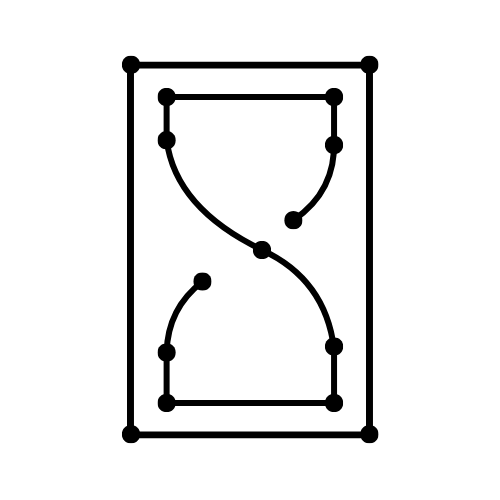

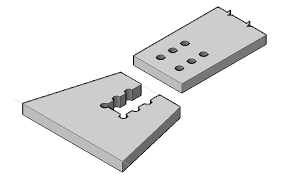

Block shear failure occurs when part of a material shears away due to a combination of tension and shear forces in a steel connection. Typically, this happens along a path where one section experiences tension and another experiences shear. The failure resembles a “block” of material tearing out from the connection, which is why it’s called “block shear.”

For example, consider a steel plate bolted to a structural member. If forces act in such a way that part of the plate experiences pulling (tension) and cutting (shear), block shear failure could happen. This failure can compromise the entire connection if not properly designed.

#Factors Contributing to Block Shear Failure

Several factors can lead to block shear failure in steel connections:

- Material Strength: Steel’s strength is critical. When stressed beyond its ultimate tensile strength, block shear failure can occur.

- Connection Type: Bolted or welded connections must be designed to withstand combined forces, otherwise block shear can develop.

- Load Conditions: Loads that create simultaneous shear and tension increase the likelihood of failure.

- Bolt Arrangement: Poorly spaced bolts or bolts placed too close to the edges can weaken a connection.

- Geometry: The size and shape of the steel plate also influence the risk of block shear.

#Analyzing Block Shear Capacity

The block shear capacity is the maximum load a connection can withstand before block shear failure happens. Engineers use the following AISC formula to calculate it:

ϕ.Rn = min [ ϕ (0.6 Fu.Agv + Fy.Ant), ϕ (0.6 Fu.Anv + Fu.Ant) ]

Where:

- ϕ is the resistance factor (typically 0.75 for block shear).

- Rn is the nominal block shear strength.

- Fu is the ultimate tensile strength of the steel (in N/mm²).

- Fy is the yield strength of the steel (in N/mm²).

- Agv is the gross area subject to shear (in mm²).

- Anv is the net area subject to shear (in mm², accounting for bolt holes).

- Ant is the net area subject to tension (in mm², accounting for bolt holes).

Step-by-Step Breakdown:

- Calculate the shear strength: The term 0.6Fu.Agv represents the shear strength along the gross area, while 0.6Fu.Anv represents the shear strength along the net area.

- Calculate the tension strength: The term Fy.Ant accounts for the tension strength at yield, while Fu.Ant accounts for tension at ultimate strength.

- Compare failure modes: Two combinations of shear and tension forces are considered, and the minimum value of the two modes determines the block shear strength.

#Design Considerations to Prevent Block Shear Failure

To avoid block shear failure, engineers must follow proper design practices:

- Ensure proper bolt spacing to prevent excessive stresses.

- Use adequately thick steel plates.

- Maintain sufficient edge distances.

- Use high-quality materials with appropriate yield and tensile strengths.

- Apply safety factors from design codes like the AISC.

#Examples of Block Shear Failure in Real-World Structures

Several notable structural failures have occurred due to block shear failure. For example, steel bridge plates have failed when their connections were not designed for combined tension and shear. Heavy industrial machinery connected to steel frames has also suffered from block shear failures, leading to structural damage.

#Preventive Measures and Best Practices for Avoiding Block Shear Failure

To prevent block shear failure:

- Follow standard design codes like AISC to ensure proper connection design.

- Use high-quality bolts and materials that meet strength requirements.

- Inspect structures regularly to detect potential block shear failures early.

- Proper detailing of connections, ensuring edge distances and bolt arrangement are optimized.

- Education and training of engineers to recognize and prevent block shear failure.

#Conclusion: Importance of Addressing Block Shear Failure in Structural Design

Understanding and addressing block shear failure is crucial in structural design. If connections are not properly designed to resist both tension and shear, the safety of the structure is at risk.